hup! Base

The hup! Base makes a hup! extension build even faster and is suitable for most site conditions. With predictable costs and timelines, the new hup! Base also provides confidence in your pricing and makes your hup! projects even easier to manage.

No diggers are required and the need for skips is reduced and sometimes even eliminated. There is far less mess and dirt on site compared to a traditional build and the need for specialist bricklayers is eliminated.

Concrete pads can be used vs full foundations, and the system is also compatible with ground screws if necessary, requiring far less excavation work on each build and less concrete needed, which further speeds up each project and reduces the risk of weather delays.

hup! Base is fully Building Regulation compliant with a U-Value of 0.18 w/m2K and red tape is simplified with system pre-approval by Stroma for speedy compliance.

Easy, Clean and Quick to Install

Hassle free

- Less mess on site

- No need for diggers

- Reduced need for skip, less waste

- No need for specialist bricklayers

- Easier project management

Fast

- Pads vs full foundations

- Compatible with ground screws

- Reduced excavation work

- Complete hup! extension in days vs weeks

- Less weather delays

Predictable

- Suitable for most site conditions

- No need to re-locate manholes

- Predictable costs

- Predictable install times

- Consistent quality of workmanship

Energy efficient

- U-Value of 0.18 w/m2K

- 100mm PIR

- Building Regulation Compliant

- Pre-approved by Stroma for extensions

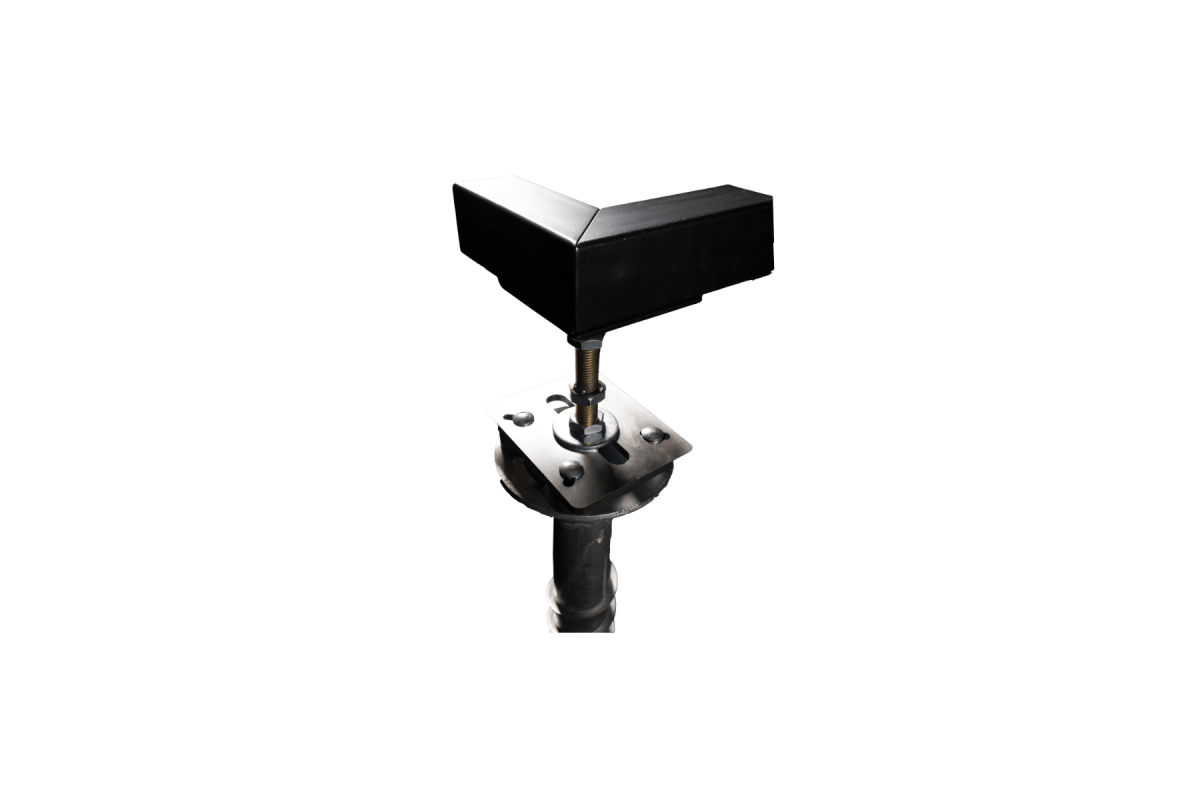

Using ground screws with hup! Base is simple

Simply contact your local ground screw company who will provide a quote for ground screw installation based on the indicative screw count given as part of your quote.

They will visit the site to check suitability for ground screws and may also be able to complete the ground preparation, and install the base as well as installing the ground screws.

Download this simple process guide which provides an overview of the process for using ground screws with hup! Base.

Ground screws

No cement, less mess and less waste, the hup! Base is also compatible with ground screws.

Ground screws are supplied through a ground screw specialist and a local installer will be recommended by hup!. They will carry out an initial site visit to assess the lateral and vertical loadings in order to confirm the length and number of ground screws required. A quote will then be supplied to cover the site assessment, ground screws and installation.

A ground screw plan will be provided based on the base loads and ground screw connectors will be supplied with your hup! Base.

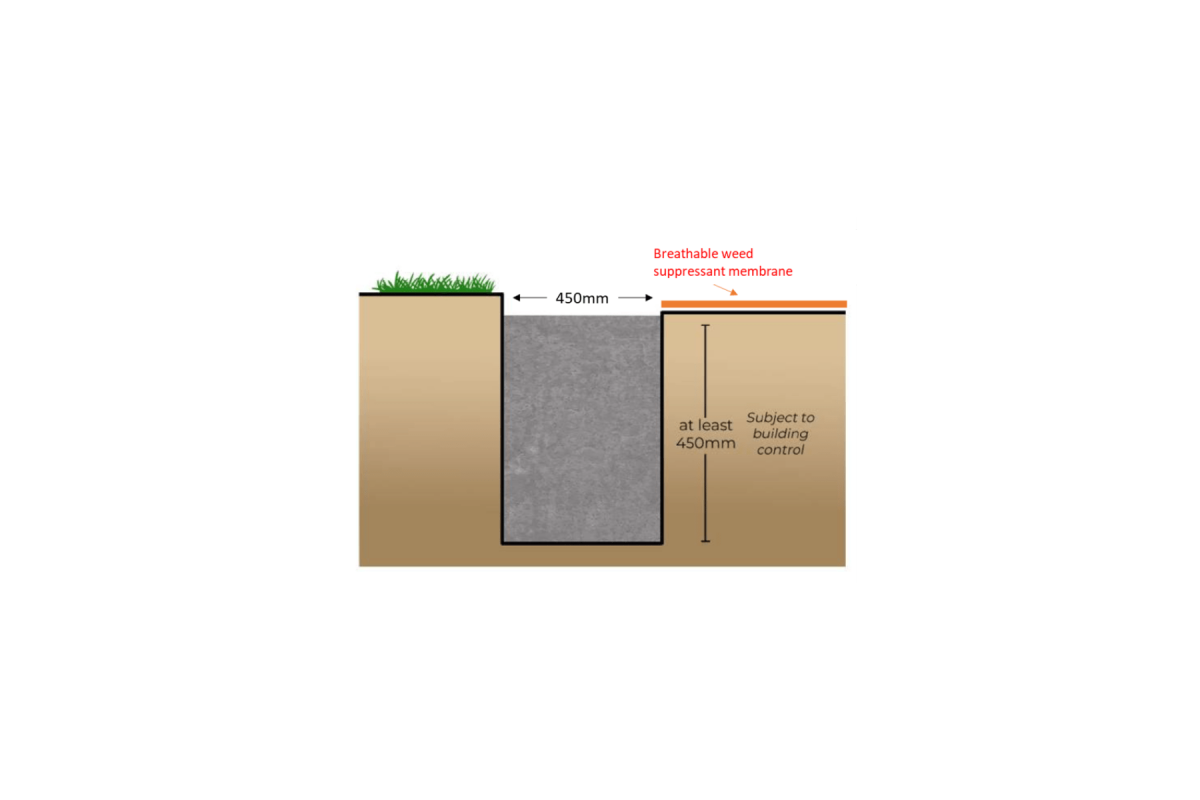

Concrete Pads

The hup! base is compatible with concrete pads which can be installed by any groundworks team and requires less cement and skips vs a traditional base. A plan of the pad location is supplied with your hup! base and breathable membrane is supplied.

To comply with Building Regulations concrete pads must be at least 450mm square and the base should be at least 150mm below the back cill to allow for adequate airflow.

Skirt Colour Options

Choose from 4 popular bricks for the hup! Base skirt or plain Pyroc: